4.0 : The technological revolution in maple sugaring

In the ever-changing landscape of maple sugaring, the advent of 4.0 technology is proving to be an essential catalyst to take the industry to new heights of productivity, efficiency, and profitability. At CDL, we are proud to present our 4.0 vision for maple sugaring and our CDL Intelligence system, designed with the unique needs of maple syrup producers in mind.

What is 4.0 in maple sugaring?

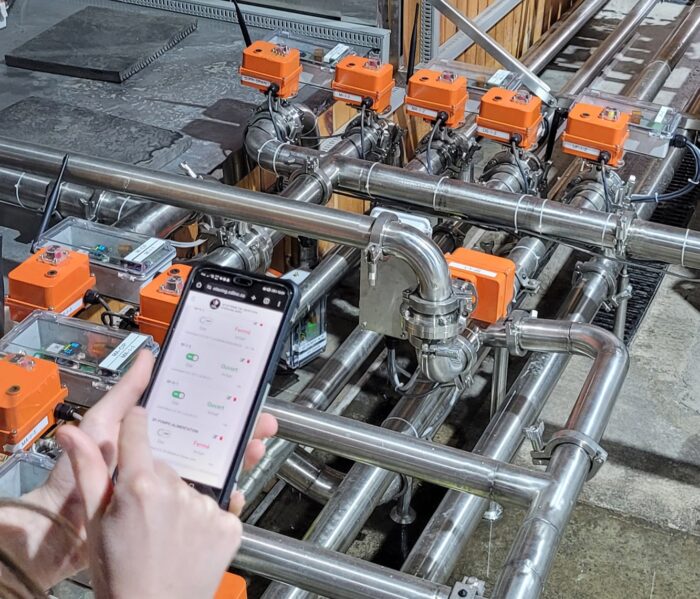

CDL’s 4.0 vision is more than just a technological evolution: it’s a true revolution in the way we organize, manage, and optimize our sugar bushes. Imagine being able to control your business remotely, in real time, from your smartphone or computer! With 4.0, you can do just that. This ability to control your sugar bush remotely offers unparalleled convenience.

CDL’s 4.0 vision isn’t just limited to remote control, either. It’s also a solution of choice that lets you monitor your sugar bush, prioritize your actions, collect and measure data, and make informed decisions based on that data. Real-time alerts keep you constantly informed about the status of your sugar bush, letting you react quickly to changes and optimize your operations.

An answer to the labor shortage

At a time when skilled labor is becoming increasingly scarce in our industry, 4.0 has the potential to be the ideal solution. By automating tasks that used to require a human touch, 4.0 reduces dependence on specialized workers while keeping performance as good as ever.

CDL’s 4.0 Vision

At CDL, we firmly believe that 4.0 is the key to profitability for maple syrup producers. In fact, the Business Development Bank of Canada (BDC) stated in one of its articles that the productivity gains from Industry 4.0 may become so significant that companies without it will not be able to achieve the same level of profitability. Our vision is simple: to make 4.0 accessible to all kinds of maple syrup producers, whether they’re passionate hobbyists, full-time workers, seasoned professionals, or even investors. For example, 4.0 technology can let full-time workers continue working while running their business more efficiently and maybe even expand, without necessarily needing to work longer hours during sugaring season. With today’s technologies, it’s possible to make your equipment work for you and still go boil with your family on weekends.

For us, 4.0 is much more than just a technological innovation. It’s an opportunity to radically transform the way you work by eliminating tasks that don’t add value and fine-tuning every aspect of your operations. Our mission is to equip you with the tools you need to boost your profitability, lower your production costs, and offer your customers a superior product.

Cut down on non-value-added activities with CDL Intelligence

Non-value-added activities, or waste, are often described as anything that adds costs without creating value for the customer. They represent a significant proportion of operations in any industry. Unlike value-added activities, which do contribute to improving the final product, non-value-added activities generate costs without helping improve the final product. This waste often takes the form of waiting or supervision on site (wasted time), transportation (avoidable travel), or lost production. As a rule of thumb, regardless of the type of industry, only 10% of all actions or tasks are truly value-added; the remaining 90% add no value to the final product.

Let’s take the example of one of the key stages in the maple syrup production process: harvesting the sap at the pumping station.

In this example, the value-added action is the harvesting of the sap. As for the non-value-added actions, there are plenty. Just think of all the trips to start or stop vacuum pumps, manage valves, clean extractors or tanks, check that equipment is working properly or deal with mechanical issues caused by freezing or overheating…

All that can be avoided with 4.0 equipment. That leaves you more time for value-added tasks.

The CDL Intelligence system is the solution to bypass the enormous time, travel, production, and monetary wastes associated with these actions. It reduces or even eliminates non-value-added actions for maple sugaring, because they can all be done at the press of a button or even automated. All you need is a smartphone or computer. An action that used to take 30 minutes can now take a second with 4.0 technology.

Towards a more efficient future

In conclusion, 4.0 marks the beginning of a new era for maple syrup production. Thanks to innovative technologies like CDL Intelligence, maple syrup producers can take their performance and profitability to new heights. At CDL, we’re proud to play a leading role in this technological revolution, and we’re committed to developing ever more advanced solutions to meet the changing needs of our industry.

Join us on this adventure towards a smarter, more efficient, and more sustainable future for maple sugaring. The possibilities are endless with 4.0, and at CDL, we’re determined to accompany you every step of the way on this journey towards innovation.