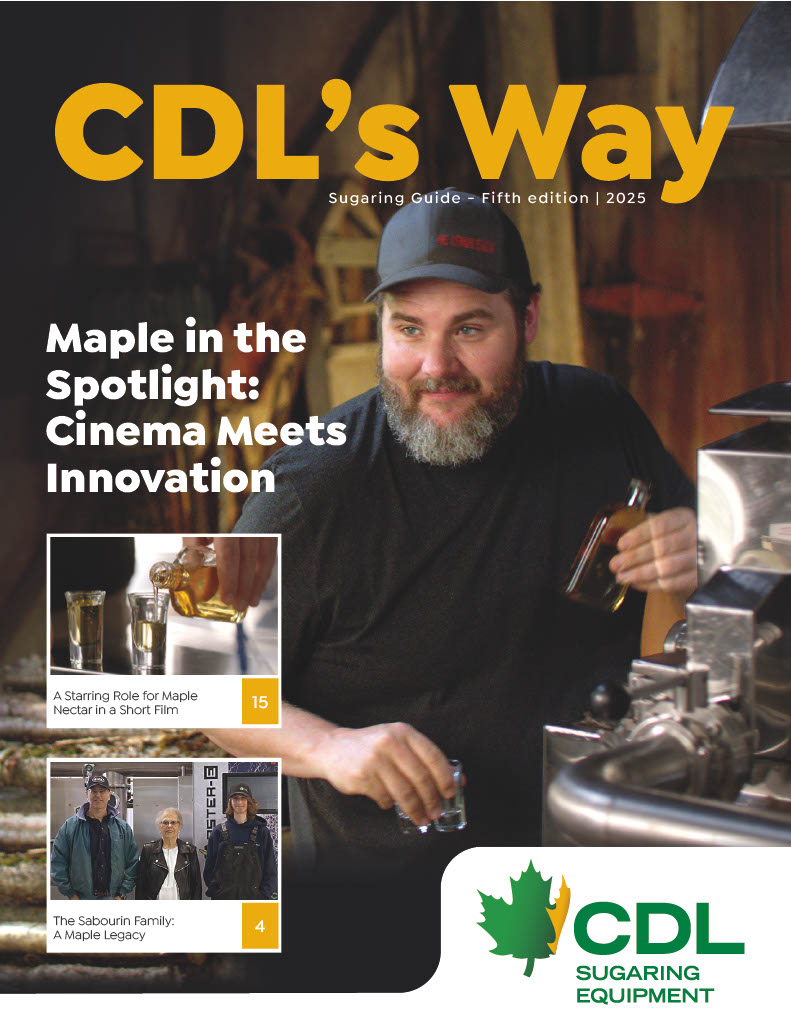

A new opportunity for maple syrup producers: maple nectar

Vallier Chabot Co-owner of CDL, gives us an update on the maple nectar project. He answers questions from Annik Perron, editor for CDL’s Way.

Annik Perron (AP)– Since 2016, your R&D team has been working on a process that allowed you to develop a new natural sweetener, maple nectar, that could benefit the industry and optimize maple resource operations. Can you remind us what this process developed by CDL consists of?

Vallier Chabot (VC)– First of all, it is important to know that this new product, which has been called nectar until now, does not replace maple syrup at all! It is a brand new nutritional ingredient that will be mainly used by the food industry. What was developed by our R&D team consists of routing maple water through a process that combines ultrafiltration, concentration, and evaporation at a low temperature so that all the original properties of the natural sap are preserved. It is very exciting from a nutritional point of view, hence the great interest of the industry. At this point, the sap has reached 60 to 70 degrees Brix, depending on the needs. At the end of all these steps, the product is stable and can be stored at room temperature, and this is what we call maple nectar. Also, the process is flexible and it is possible to produce a customer’s desired Brix.

From left to right: raw maple sap, ultrafiltered sap, ultrafiltered concentrated sap, 66 Brix maple nectar.

AP– What are the project’s developments in the past year?

VC– We can now say that we are in phase three of this project. After having completed the work on the production equipment, we now need to position the product in the market, and there is no doubt that we will be able to attract several potential partners with an ingredient that preserves the nutritional qualities of maple water. It is definitely current in food trends to want to decrease or eliminate refined liquid sugars by using more natural agents that offer the same taste. The industry will need to do its own testing first to fully understand how to use the product. This is what we need to accomplish in the next year in collaboration with some of the major players. The technology will be patented and there is a lot of interest in this innovation.

AP– Do you envision this product consolidating CDL’s leadership in promoting maple syrup production?

VC– Absolutely. At CDL, we are very proud of this innovation because it has the potential to advance the entire maple syrup industry. The nectar will be added to the range of products from maple trees, with a possible large-scale industrial use. Maple syrup production is destined for a bright future and we are very happy to participate in its progress with our innovations.